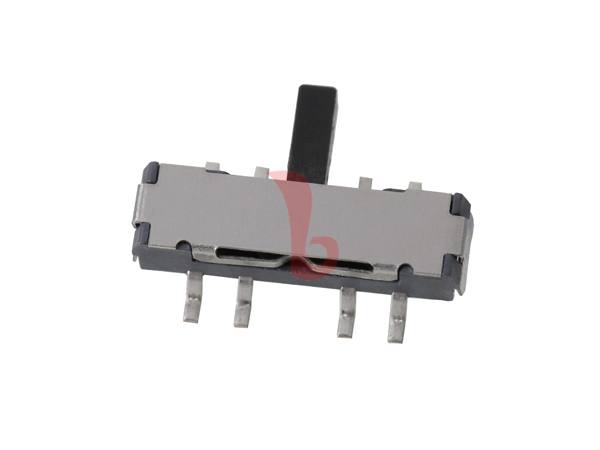

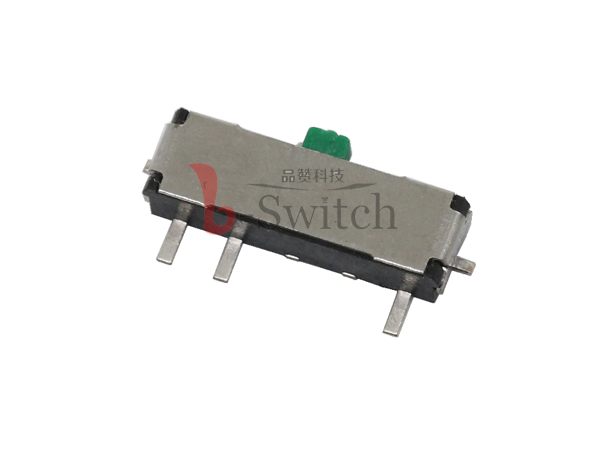

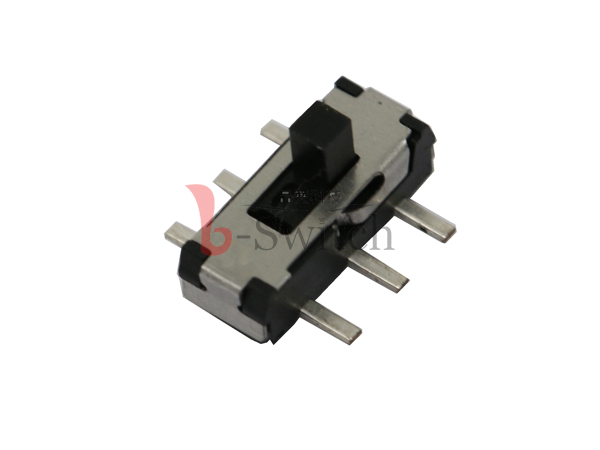

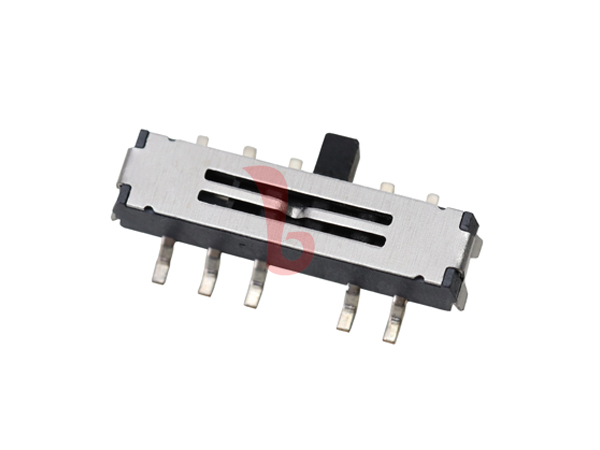

卧式八脚三档拨动开关

品牌:G-Switch/品赞

规格:9.7×2.7×2.7mm

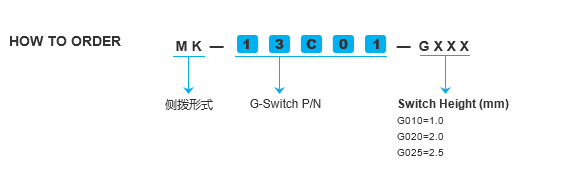

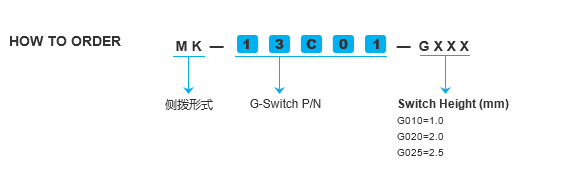

型号:MK-13C01-GXXX

包装:3000/盘

声明:有关于产品的规格、参数、寿命、工作温度、手感、防水等级等数据,只代表品赞电子内部的测试结果,如需详细测试方式,请联系品赞业务人员。

基本说明

Specification

FUNCTION: Momentary action

CONTACT ARRANGEMENT: 1P2T SLIDE SWITCH

Electrical

ELECTRICAL SPECIFICATIONS:DC 12V 0.5A DC 6V 1.0A

CONTACT RESISTANCE (CR):100mΩMAX

INSULATION RESISTANCE(IR):100M ohm 100V DC

COMPRESSIVE STRENGTH (WV):AC 250V for 1min

STORAGE HUMIDITY:(40°C)<85%RH

ELECTRICAL LIFE:10,000 times.

SWITCH TRAVEL:2.0±0.2mm

Environmental

OPERATING TEMPERATURE: -20˚C to +70˚C

Molde code:

| 序号 | 型号 | 规格 | PDF下载 |

| 1 | MK-13C01-GXXX | 三档 9.7×2.7×2.7mm |

|

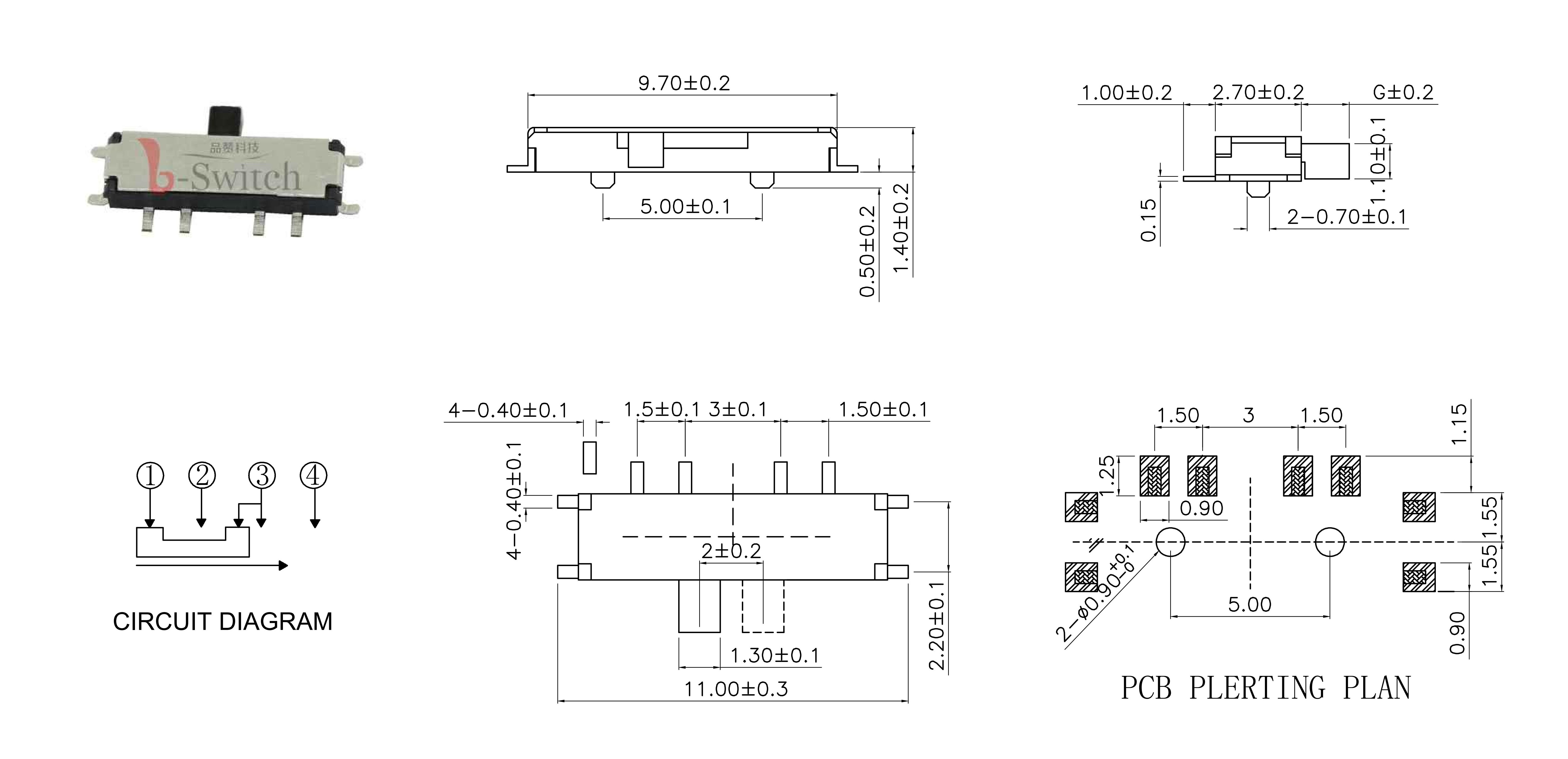

尺寸图

产品说明

微型拨动开关使用说明书:

微型拨动开关注意事项

1、慎用化学品

拨动开关底板因使用了诸如聚碳酸酯等合成树脂,所以应避免将电位器暴露于氨、胺、碱溶液、苏烃、酮、酯、卤烃等化学物品浓烈气氛中。

2、慎用助焊剂

焊锡时应避免使用水溶性助焊剂,否则将会对构成拨动开关的金属和其他材料产生不良影响。

3、焊锡

布线设计和焊锡方法应避免导致,熔锡流到PC板上平面,这样会引起接触不良。

4、低温工作

当产品是用于低温环境时,如寒带的汽车收音机或汽车音响等,本公司按客户要求提供手感舒适产品,请定货时加以说明。

5、滑柄长度

长度越短越好(至少5mm)在滑柄的宽度A不变情形下,滑柄长度愈短,手感愈好,另出力点愈高,手感愈差。

6、 驱动臂

切勿使操作点远离滑柄中心线,基于同样理由,两者距离B越短越好。

G-Switch 东莞品赞电子科技有限公司:www.dg-switch.com

| ITEM 项目 | TEST CONDITIONS 测试条件 | PERFORMANCE 规格 | ||

|

4.1 |

CONTACT RESISTANCE 接触电阻 |

MEASURED AT 1KHz SMALL CURRENT(100mA OR LESS) 在1KHz微小电流(100mA以下)测试. |

100mΩMAX. 100毫欧以下 |

|

|

4.2 |

INSULATION RESISTANCE 绝缘电阻 |

APPLY A VOLTAGE OF 500V DC FOR 1 MIN. TO FOLLOWING PORTIONS AFTER WHICH MEASUREMENT SHALL BE MADE. (1)BETWEEN BODY AND TERMINAL。 (2)BETWEEN TERMINALS。 输入500V DC 电压1分钟,按以下接触方法测试: (1)排脚相互之间。 (2)排脚与外壳之间。 |

100MΩMIN. 100兆欧以上. |

|

|

4.3 |

DIELECTRIC STRENGTH 耐电压 |

AC 500V rms(50-60Hz)FOR 1 MIN TRIP CURRENT:0.5mA (1)BETWEEN TERMINALS. (2)BETWEEN INDIVIDUAL TERMINAL AND FRAME. 输入AC 500V(50-60Hz)电压,1分钟感度电流为0.5mA, 按以下接触方法测试: (1)排脚相互之间 (2)排脚与外壳之间. |

WITHOUT DAMAGETOPARTS ARCING OR BREAKDOWN ETC 没有绝缘破坏等异常 |

|

| 5、MECHANICAL CHARACTERISTICS (机械性能规格) | ||||

| ITEM 项目 | TEST CONDITIONS 测试条件 | PERFORMANCE 规格 | ||

|

5.1 |

OPERATING FORCE 作动力 |

MEASUREMENT SHALL BE MADE AT THE NEAREST POINT OF THE COMPONENTOR AT THE POINT 3mm FROM THE TIP OF THE ACTUATOR(KNOB). 在距离胶柄前端3mm作测定点. |

300gf±100gf |

|

|

5.2 |

TERMINAL STRENGTH 端子强度 |

A STATIC LOAD OF(500gf)SHALL BE APPLIED TO THE TERMINAL FOR 15 SEC,IN ANY DIRECTON. 在排脚前端任意一个方向加500gf力度测试,时间为15秒. |

MECHANICAL AND ELECTRICAL CHARACTERISTICS SHALL BE SATISFIED WITHOUT LOOSENESS OF ACTUATOU. 在端子中没有裂开,松动等异常, 满足于机械、电器性能。 |

|

|

5.3 |

DISPLACEMENT OF ACTUATOR (KNOB) 柄 强 度 |

A STATIC LOAD OF 10N(1Kgf)SHALL BE APPLIED TO THE TOP OF THE ACTUATOR(KNOB)AND THEN DESPLACEMENT SHALL BE MEASURED TO THE DIRECTION OF THE ARROW. 在柄的前端施加1Kgf的力度,位移应沿印记的方向上定. |

THE LEVER SHALL HAVE NO SERIOUS DEFORMATION AND FUNCTION IS NORMALLY. 柄部无严重变形,可以正常工作. |

|

| 6、ENDURANCE CHARACTERISTICS (耐久性) : | |||||||||

| ITEM 项目 | TEST CONDITIONS 测试条件 | PERFORMANCE 规格 | |||||||

|

6.1 |

LIFE TEST 寿命试验 |

WITHOUT LOAD: AN ACTUATOR SHALL BE SUBJECT TO 10,000 CYCLES AT A SPEED OF 15 TO 18 CYCLES FOR 1 MIN. 无负荷: 操作者以每分钟15—18回的频率作10,000 回之无负荷测试. |

(1) CONTACT RESISTANCE(接触电阻) 200mΩ MAX.200毫欧以下. (2) INSULATION RESISTANCE(绝缘电阻) 50MΩ MIN. 50兆欧以上. (3) WITHSTAND VOLTAGE(耐电压) AC 500V,1 MINUTE.AC 500V 1分钟 (4) OPERATING FORCE(作动力) ±30%INITIAL VALUE. 变化范围初始值±30% (5) WITHOUT DAMAGE TO PARTS ARCING OR BREAKDOWN ETC. (测试后外表无损伤,并且满足机械性能) |

||||||

|

6.2 |

SOLDERA- BILITY TEST 可焊性试验 |

THE TOP OF THE TERMINALS SHALL BE DIPPED 2mm IN THE SOLDER BATH OF 260±5℃ FOR 3±0.5 SECONDS. 端子顶部被浸入锡焊池中2mm深,温度为 260±5℃,时间为3±0.5秒. |

THE AREA OF SOLDERING SHOULD BE OVER 75% 焊接面积要有75%以上. |

||||||

|

6.3 |

RESISTANCE TO SOLDERING HEAT TEST 耐焊性试验 |

(1)TEMPERATURE AND IMMERSING TIME 温度及浸锡时间

IMMERSION DEPTH UP TO THE SURFACE OF THE BOARD THICKNESS OF PRINTED WIRING BOARD 1.6mm. 浸锡深度: 浸锡深度至基板(PCB)表面,基板厚度为1.6mm. |

THERE SHALL BE NO DEFORMATION OR CRACKS IN MOLDED PART. 外观无异常,满足于机械、电器性能。 |

||||||

|

6.4 |

COLD TEST 耐冷试验 |

THE SWITCH SHALL BE STORED AT A TEMPERATURE OF -25±3℃ FOR48HOURS. THEN THE SWITCH SHALL BE MAINTAINEDAT STANDARD ATMOSPHERIC CONDITIONSFOR 1 HOUR AFTER WHICH MEASUREMENTSHALL BE MADE. 放置在温度-25±3℃中48小时后,再将放置在常 温常濕的环境中1小时后进行测试. |

|||||||

| ITEM 项目 | TEST CONDITIONS 测试条件 | PERFORMANCE 规格 | |

|

6.5 |

HEAT TEST 耐热试验 |

THE SWITCH SHALL BE STORED AT A TEMPERATURE OF 70±2℃ FOR 48 HOURS. THEN THE SWITCH SHALL BE MAINTAINED AT STANDARD ATMOSPHERIC CONDITIONS FOR 1 HOUR AFTER WHICH MEASUREMENT SHALL BE MADE. 放置在温度70±2℃中测试48小时后,再将放置在常温常濕的 环境中1小时后进行测试. |

THERE SHALL BE NO DEFORMATION OR CRACKS IN MOLDED PART. 外观无异常,满足于机械、电器性能. |

|

6.6 |

HUMIDITY TEST 潮濕试验 |

THE SWITCH SHALL BE STORED ATA TEMPERATURE OF 40±2℃ AND A HUMIFITY OF 90% TO 95% FOR 96 HOURS.THEN THE SWITCH SHALL BE MAINTAINED AT STANDARD ATMOSPHERIC CONDITION FOR 1 HOUR AFTER WHICH MEASUREMENT SHALL BE MADE. 放置40±2℃的相对湿度为90%~95%环境中96小时后,再将放置在常温常濕的环境中1小时后进行测试. |

|

|

6.7 |

STANDARD ATMOSPHEIC CONDITIONS 测试标准状态 |

UNLESS OTHERWISE SPECIFIED. THE STANDARD RANGE OF ATMOSPHERIC CONDITIONS FOR MAKING MEASUREMENTS AND TESTS ARE AS FOLLOWS: (1) AMBIENT HUMIDITY:5℃ TO 35℃ (2) RELATIVE HUMIDITY:45% TO 85% (3) AIT PRESSURE :86Kpa TO 106Kpa 在没有指定的情况下测试温度、湿度、气压如下: (1) 温度为5℃—35℃. (2) 湿度为45%—85%. (3) 气压为86Kpa—106Kpa. |

|

|

6.8 |

PRACTICAL TEMPERATURE RANCE 使用温度范围 |

-16℃~+60℃. 在-16℃~+60℃温度内使用. |

|

微型拨动开关注意事项

1、慎用化学品

拨动开关底板因使用了诸如聚碳酸酯等合成树脂,所以应避免将电位器暴露于氨、胺、碱溶液、苏烃、酮、酯、卤烃等化学物品浓烈气氛中。

2、慎用助焊剂

焊锡时应避免使用水溶性助焊剂,否则将会对构成拨动开关的金属和其他材料产生不良影响。

3、焊锡

布线设计和焊锡方法应避免导致,熔锡流到PC板上平面,这样会引起接触不良。

4、低温工作

当产品是用于低温环境时,如寒带的汽车收音机或汽车音响等,本公司按客户要求提供手感舒适产品,请定货时加以说明。

5、滑柄长度

长度越短越好(至少5mm)在滑柄的宽度A不变情形下,滑柄长度愈短,手感愈好,另出力点愈高,手感愈差。

6、 驱动臂

切勿使操作点远离滑柄中心线,基于同样理由,两者距离B越短越好。

G-Switch 东莞品赞电子科技有限公司:www.dg-switch.com

- 上一篇:卧式十脚四档拨动开关

- 下一篇:立式八脚三档拨动开关

推荐产品

轻触开关资讯

拨动开关资讯

检测开关资讯

轻触开关 >

TYPE-C连接器 >

关于我们 >

联系我们 >

电话:0769-82388879

传真:0769-81888689

手机:131-4326-8188 柯先生

邮箱:yehai@g-switch.cn

地址:东莞市滨海湾新区信鸿欧菲光科创中心2号厂房701室

扫码咨询

公安备案号 : 44190002003787 京ICP证000000号 G-Switch 东莞品赞电子

品赞电子专业生产高质量轻触开关、防水轻触开关、轻触按键开关、Type-c连接器、防水Type-c母座等!电话:0769-82388879

技术支持:恒点互联